Brief Introduction

Shine Star Eng. Steel & Welding LLC was established in 2005 as a general engineering, fabrication and trading company, to handle a diverse range of oil field fabrication and machining jobs for customers both in UAE and abroad.

Shine Star Eng. capability includes:-

Structural fabrications, Pipe work fabrications, Skid Fabrications, Fabrication/repair/alterations of ASME certified Pressure Vessels and Pressure parts, Machining and reconditioning of mechanical components, Site Fabrication and Erection of pipe works, mechanical structures, equipment.

The Fabrication Shops comprises of 20,000 sqft covered area and the open yard is of 30,000 sq ft. The machinery includes the rolling machine, shearing machine and Drilling machine The fabrication shop has expertise to handle Carbon Steel/Stainless Steel/Duplex/ Super Duplex Stainless Steel & Inconel Material.

The fabrication shop is equipped with Welding Machinery to carry out welding processes of GMAW, GTAW, SMAW and SAW processes.

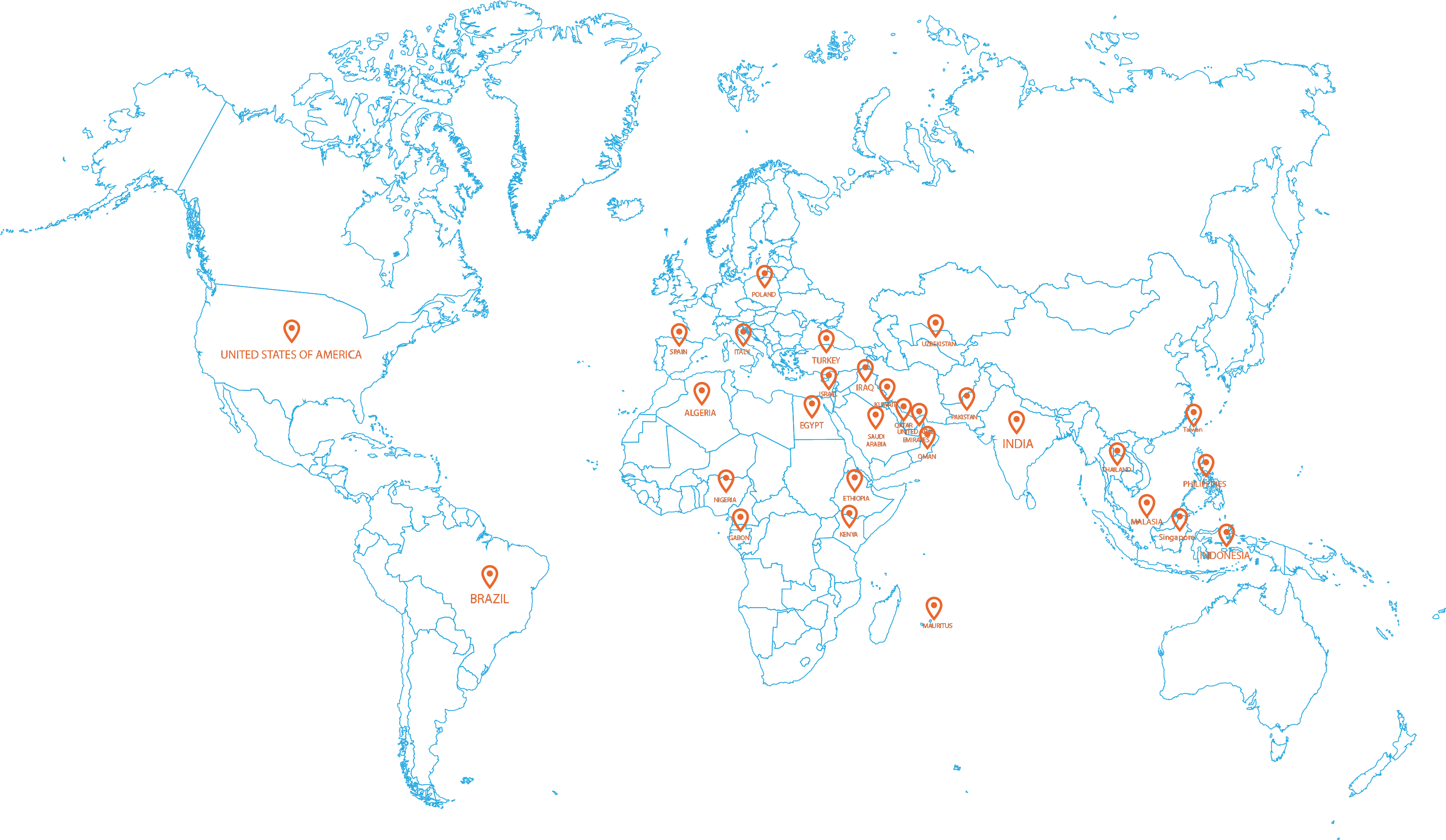

Project Delivered Across the World